Lean Manufacturing: Driving Efficiency Toward Sustainable Growth

Lean Manufacturing is a management philosophy and set of tools that seeks to eliminate waste, improve quality, and deliver greater value to customers. Originating from the Toyota Production System, Lean is now widely used across industries to boost productivity while reducing resource consumption.

What is Lean Manufacturing?

Lean Manufacturing is a systematic method for eliminating waste (muda) in production systems. The objective is to provide the customer with higher value while using fewer resources — less time, energy, and materials — without sacrificing quality.

The Core Philosophy

At the heart of Lean is continuous improvement (Kaizen). Organizations continuously inspect and refine processes to remove non-value-adding activities and create smoother flow across the production cycle.

The Seven Types of Waste (Muda)

- Overproduction — producing more than required

- Waiting — idle time between operations

- Transport — unnecessary movement of materials

- Extra Processing — doing more work than needed

- Inventory — excess raw materials or finished goods

- Motion — inefficient worker movement

- Defects — errors, rework, and scrap

Key Tools & Techniques

- 5S — Sort, Set in order, Shine, Standardize, Sustain

- Value Stream Mapping (VSM) — visualize and improve flow

- Just-in-Time (JIT) — produce only what is needed, when needed

- Kanban — visual signaling to control inventory/work-in-progress

- Poka-Yoke — error-proofing mechanisms

- Total Productive Maintenance (TPM) — keep equipment reliable

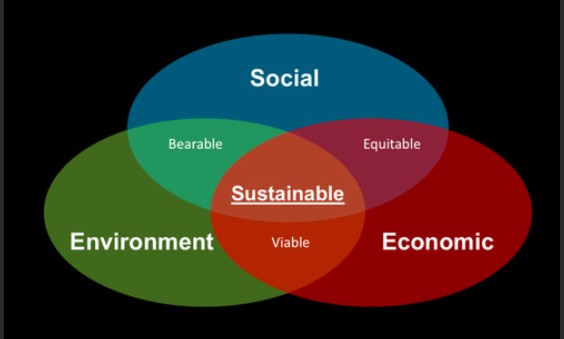

Lean & Sustainability

Lean reduces waste and improves process efficiency — outcomes that directly support sustainability goals. Lower scrap, reduced energy use, and streamlined material flows help companies reduce their environmental footprint while improving profitability.

Benefits of Lean

- Higher efficiency and lower production costs

- Improved quality and fewer defects

- Shorter lead times and faster delivery

- Stronger employee engagement and safety

Common Challenges

Adopting Lean requires cultural change, training, and ongoing leadership commitment. Organizations often face resistance to change and need to ensure continuous governance to sustain improvements.

Lean in the Digital Age

Industry 4.0 technologies amplify Lean results — IoT sensors, data analytics, and AI improve predictive maintenance, reduce downtime, and enable real-time flow optimization (Lean 4.0).

Practical Steps to Start

- Map a value stream to identify wastes and bottlenecks.

- Run short Kaizen events to fix high-impact issues.

- Implement 5S and standard work on pilot lines.

- Measure results and scale improvements across operations.

Conclusion

Lean Manufacturing is a pragmatic route to sustainable productivity. When combined with environmental practices (Green Manufacturing) and lifecycle thinking (Sustainable Manufacturing), Lean becomes a powerful engine for responsible industrial growth.

Leave a Comment